The Impact of Weather on Productivity

Weather conditions can play an important role in the productivity of work on site. Typically, productivity is impacted positively by good weather and negatively by adverse weather. The greatest impacts are generally felt on activities taking place outside, particularly on weather-sensitive operations such as earthworks, concrete, etc., since measures such as hoarding and heating can be used to reduce or eliminate impacts of weather on interior work (although often at additional cost).

This article discusses loss of productivity due to adverse weather and examines certain industry studies available on this topic, with a view to informing the reader of their often limited application and the pitfalls of erroneous application.

How Does Weather Impact Productivity?

There are various ways that weather can impact productivity on site. Temperature (both cold and hot), humidity and precipitation are all factors that impact not only the productivity of direct labour, but also the productivity/efficiency of equipment and the composition and suitability of materials.

Cold versus Hot Weather Impacts on Labour

Labour productivity can be significantly impacted by adverse cold or hot weather, due to both psychological and physiological effects.

Work undertaken at cold temperatures can be impacted by cold weather-related injuries (frostbite, hypothermia, increased potential for accidents), depression or decreased morale, errors in judgement, overall decrease in quality of work, difficulties with tactile manipulation, complaints and unscheduled work stoppages (i.e.: to seek warmth), etc.

Work undertaken at hot temperatures can be impacted by hot weather-related injuries (heat stroke, sunburn, heat exhaustion, dehydration), irritability or decreased morale, errors in judgement, lethargy, overall decrease in quality of work, increase in breaks for water or to seek shelter from the sun or other unscheduled work stoppages, etc.

Fine and Gross Motor Skills

With respect to tasks involving direct labour, it is important to recognize that weather impacts fine motor skills differently than gross motor skills.

Cold weather may make tasks involving fine motor skills, such as those requiring finger/hand dexterity and other tactile manipulation more difficult and time consuming while having little to no major effect on those involving gross motor skills, such as walking, lifting objects, etc.

Conversely, hot weather may make exerting activities involving gross motor skills more taxing while having little to no negative impact on those involving fine motor skills.

Site Conditions and Other Environmental Factors

Heavy rainfall or snowfall can present a hazard due to low visibility or slippery conditions, as well as impede progress on certain operations due to the need to de-ice, clear snow accumulation or pump excess water accumulation (all of which may also entail additional costs).

Depending on the severity of the weather, work may need to be suspended.

There are also other, less obvious ways that weather or seasonal conditions can affect the productivity of work on site. Across Canada, it stays darker later in the morning and gets darker earlier in the evening during the winter period, resulting in shorter days. Weather can affect activities involving condition- or temperature-sensitive materials, such as concrete, by restricting when and how work can be executed. Weather may also have an impact on the condition of in situ material on site. For example, soil to be excavated or used as fill may become frozen if exposed to cold temperatures or saturated if exposed to rain, potentially affecting suitability for its intended use.

Considerations for Owners and Contractors

To the extent that weather conditions can be expected and are reasonable, they should be considered by both owners and contractors prior to construction.

Owners, for example, should take weather into account when establishing contractual milestones, particularly if work will need to take place over winter periods or very hot summer months.

Contractors, for their part, should consider the period during which work will be taking place when determining their bid price. Weather should also be considered as the contractors develop their project schedule, such that the potential for reduced productivity during certain periods is taken into account in determining activity durations and required resources. If possible, contractors should also make every effort to schedule weather-sensitive operations around optimal weather periods.

In the event that delays are incurred during project execution, it is possible that work can be pushed into a different season than originally planned. In these situations, activities may need to be undertaken in conditions which are less than optimal, despite appropriate planning. In such a situation, a contractor could be in a position to make a claim if the cause of this delay was not under their responsibility. A more detailed discussion on this point is outside the scope of this article.

It is important to note that simply encountering adverse weather events is not necessarily grounds for a claim. It is therefore imperative to establish the causal link between weather and the alleged impacts. The contractor’s planning must be taken into consideration when evaluating impact or entitlement. For example, it may be inappropriate to claim for winter conditions if the work was already planned to take place over a winter period. Similarly, consider whether the work taking place was truly exposed to the alleged adverse weather. For instance, interior work may not be adversely affected by weather impacts in the same way as other activities. Finally consider whether measures were employed (or could have been employed) to mitigate or eliminate the impact of adverse weather, such as heated clothing, weather resistant materials (concrete mixes, membranes, etc.), or heating and hoarding.

All said, when unanticipated adverse weather conditions are encountered on a project, it may be necessary for contractors to measure the resulting loss of productivity.

Measuring Loss of Productivity

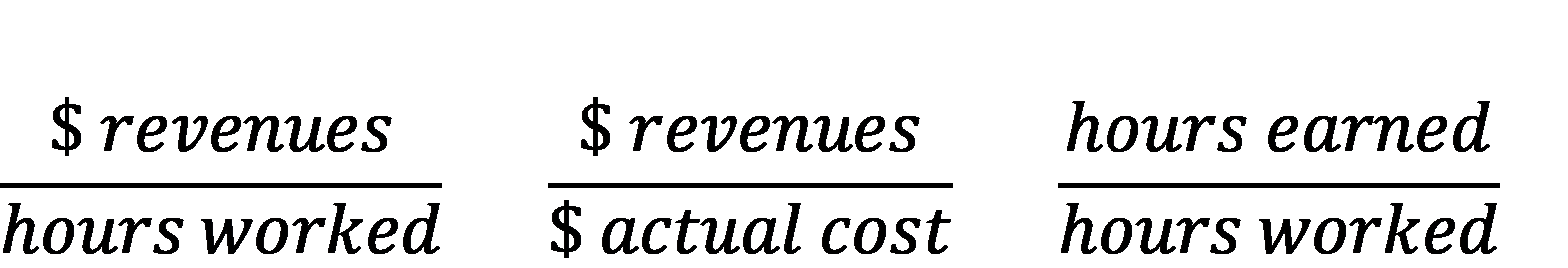

In simple terms, productivity is measured as a function of output (the work produced in units) per unit of input (hours required or cost incurred). Other frequently used productivity measurements include:

There are several different methods used to measure loss of productivity, some more preferable than others.

The Association for the Advancement of Cost Engineering International (AACEi) published a recommended practice for “Estimating Lost Labor Productivity”1 which outlines the common methods for measuring loss of productivity in order of preference, namely:

- Project Specific Studies (Measured Mile)

- Project Comparison Studies

- Specialty Industry Studies

- General Industry Studies

- Cost Basis

- Productivity Impact on Schedule

The American Society of Civil Engineers (ASCE) also published a standard for “Identifying, Quantifying and Proving Loss of Productivity”2 which similarly classifies methods of measuring loss of productivity, albeit more broadly. Once again, the measured mile was indicated as the preferred method, followed by industry studies and finally the total cost method. The following sections will present the preferred “measured mile” method, as well as some specialty industry studies on weather.

Measured Mile

The most convincing method of measuring loss of productivity is undoubtedly the “measured mile” approach. It compares actual productivity achieved on a project during unimpacted periods or “normal periods” with the actual productivity achieved during periods affected by the alleged impacts. It is based on actual project data and inherently accounts for contractor inefficiencies and/or estimating errors. Associated damages are then calculated based on the difference in productivity rates. As the AACE states in its recommended practice:

The Measured Mile calculation is favored because it considers only the actual effect of the alleged impact and thereby eliminates disputes over the validity of cost estimates, or factors that may have impacted productivity due to no fault of the owner.3

A hypothetical example of the application of a measured mile analysis is shown in Figure 1.

Figure 1 - Example of a measured mile analysis

Wherever possible, the measured mile method, or some modified version of the measured mile, should be used for calculating loss of productivity. Unfortunately it may not be feasible to do so if:

- the required data for a detailed productivity analysis is not available or is unreliable;

- several causes contributed to the productivity loss, but only one cause is compensable; or

- the productivity loss has to be included in a change order quantification prior to the execution of the change (forward costing).

Short of “guesstimating,” one of the only alternative methods for quantifying a distinct productivity loss may be the use of industry studies for the cause in question, but not without great caution.

Industry Studies

Since weather has the potential to significantly impact productivity on a project, numerous studies have been conducted over the years in an attempt to evaluate these potential impacts. The studies performed show a clear correlation between weather (in terms of temperature, humidity, precipitation, wind, light, etc.) and productivity, although to a varying degree. However, most of these studies date back to the 70s and 80s, or even earlier.

While several more recent articles and papers have been published which provide interesting general commentary on the impacts of weather on construction, there unfortunately appears to be little to no new research focused specifically on this topic. It is therefore important to keep in mind that the results of older studies would not take into account changes in climate data over the years, as well as the use of more recent emergent technologies and practices which certainly help to mitigate the weather-related impacts on productivity demonstrated by studies on the topic. As an example, heated clothing can alleviate some impacts on direct labour working in cold environments, while the use of certain materials (such as cold weather concrete mixes) can allow weather-sensitive operations to be performed in otherwise unfavorable conditions.

Regardless, some studies,4 which are still often cited in the industry, were conducted by the following organizations and are summarized in the subsequent sections:

- National Electrical Contractors Association (NECA)

- U.S. Army Corps of Engineers

- Koehn and Brown

- U.S. Army Cold Regions Research and Engineering Laboratory

National Electrical Contractors Association (NECA)5

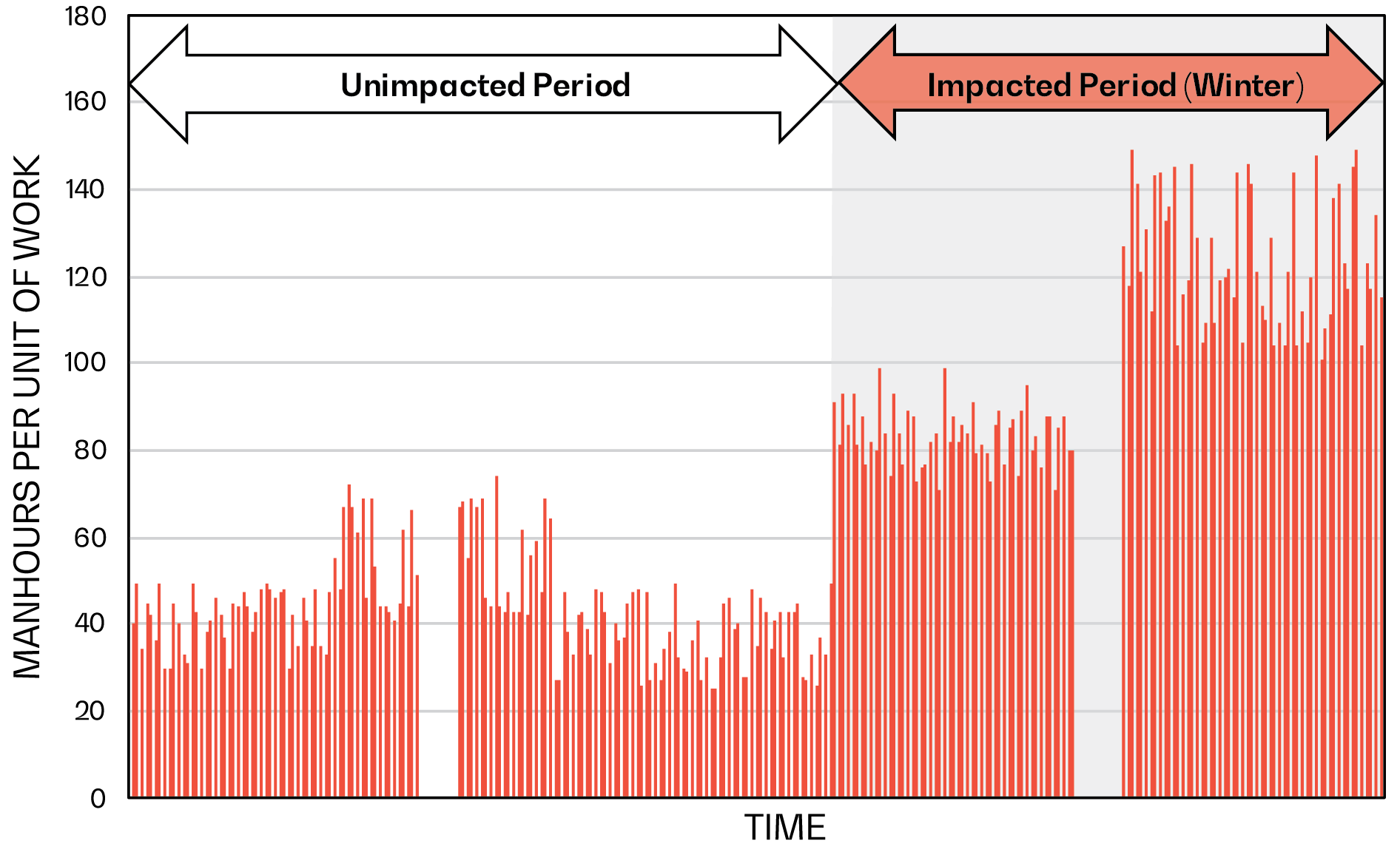

In 1974, NECA conducted a study entitled “The Effect of Temperature on Productivity,” which was republished in 2004. This study evaluates the effects of temperature and humidity on productivity, specifically related to electrical work.

The productivity of two electricians (journeymen) installing duplex receptacles on work panels was measured at different combinations of temperature and relative humidity.

The NECA study generally found that the workers’ performance decreased at temperatures above 80°F and below 40°F, and that while humidity did not play a significant factor in the 30°F to 80°F range, it resulted in an important reduction in productivity at elevated temperatures. Productivity was found to decrease with high humidity at colder temperatures; however, it is the temperature that plays a much more significant role in very cold conditions. Figure 26 presents a compilation of the different curves that relate productivity to effective temperature and relative humidity (RH).

Figure 2 - Adapted productivity curves at 20 to 90 percent relative humidity

We note that the NECA study presents productivity in tabular and graphical formats.

While the study itself did not directly evaluate the effect of windchill on productivity, recommendations on adjusting for windchill were provided.

Overall, the NECA study provides insight into how work performance can be influenced by the interaction of temperature and humidity, and could be used as a tool for factoring estimates, for planning and scheduling or to support time extension requests and claimed damages determined through other means. That said, this study is based on only two journeymen electricians performing “fine motor skill” tasks, and therefore should not be blindly or directly applied to any or all tasks or trades.

U.S. Army Corps of Engineers7

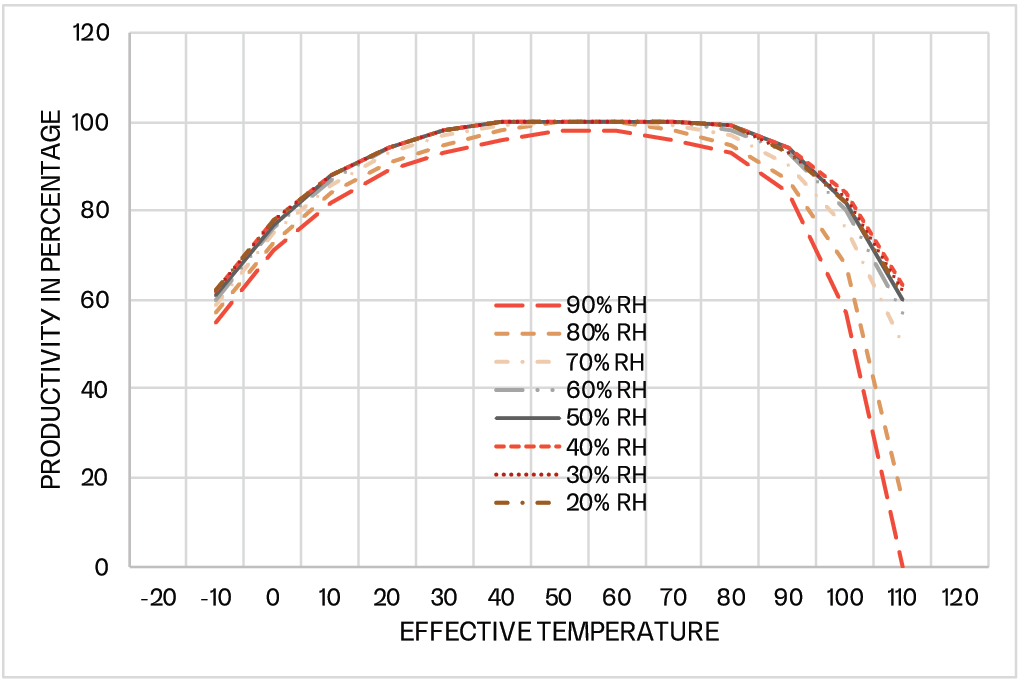

In 1984, a study entitled “AFCS (The Army Facilities Components System) Climactic Zone Labor Adjustment Factors” was performed and published for the U.S. Army Corps of Engineers, Construction and Research Laboratory. The study was intended to improve upon, update and/or validate a set of efficiency factors and labour adjustment factors previously developed in 1971. The data used was collected from previous studies containing productivity data on different trades (including masonry, electrical work, and iron/steel work) from different countries. The results of the study were summarized in various tables, including those presenting the climactic labor productivity factors by climactic zone and labour adjustment factors by climactic zone, as well as a normalized regression curve of temperature versus productivity. This regression curve is presented in Figure 3.8

Figure 3 - Regression curve of temperature versus productivity

As can be seen in Figure 3, productivity is affected as a function of effective temperature, decreasing both for cold and hot conditions. Per this study, productivity can be estimated below 50% at approximately -10°F, continuing to decrease as effective temperature decreases, as well as at approximately 110°F, again continuing to decrease as effective temperature increases.

The labour adjustment factors presented in the study have been criticized for being quite general in their application, as they do not target a specific activity or trade and the regions or countries that they encompass are very broad.9

Koehn and Brown10

In 1984, Enno Koehn and Gerald Brown conducted a study based on historical data from several previous studies in order to evaluate the effects of temperature and humidity on productivity, in hot and cold environments. The statistical analysis was performed based on productivity data for excavation, erection, masonry and carpentry activities, electrical work, as well as for general laborers. The temperature data analyzed was used to derive two equations for calculating productivity factors (one for cold weather and one for warm weather).

These equations are intended to be used to estimate or calculate the weather-related productivity for an overall project, based on the climactic conditions of the site location. That said, the authors caution that the results of this study may not be applicable or may need to be adjusted given certain factors related to the crew and the complexity of the tasks performed. Concerns have also been raised in the industry regarding how the data from the various sources were treated and normalized, as well as whether combining data from different studies involving different trades could be misrepresentative.11

U.S. Army Cold Regions Research and Engineering Laboratory12

In 1986, a “cold environment factor” was developed for the U.S. Army Cold Regions Research and Engineering Laboratory, intended to indicate the productivity and efficiency impacts of cold environment or cold weather conditions on exterior work, both for labour (manual tasks) and equipment. This analysis, published in a report entitled “Effect of Cold Weather on Productivity”, was based on data from various construction industry and military surveys. As such, a wide range of activities and types of work have been considered in this study, including but not limited to, piling, earthworks, runway or roadway construction and repair work.

The U.S. Army study considered several variables, specifically the temperature, windspeed and the intensity of precipitation in developing the cold environment factors. From the data used, nomographs were developed for estimating the cold environment factors for manual tasks and equipment performance.

The study itself cautions that the cold environment factors give an indication of the effort required to perform an activity and the likely effect of cold weather on said activity under given conditions, but that field tests would be required to determine actual impacts and whether modifications to the cold environment factors would be necessary. Furthermore, since the factors were developed based on a wide range of equipment and tasks, they should be considered “at best, typical tentative values.”13

Caution for the Use of Industry Studies

Contractors and their claims consultants often rely on industry studies to demonstrate loss of productivity; however, in many cases the studies relied upon have very little to do with the specific situation under scrutiny. In fact, they may have never examined the actual study and simply relied on a single chart reproduced in a book or by a trade association.

For instance, a study may indicate reduced productivity caused by certain weather conditions–say wind–and provide associated factors to estimate this loss of productivity, but if such weather conditions did not in fact have a material impact on the work, it would not be appropriate to base any loss of productivity calculation on this study.

Similarly, if, for example, a study on mechanical/electrical work is being used to evaluate loss of productivity for earthworks operations, this would not be an appropriate application. It is therefore critical that any study being referenced or relied upon, in the absence of project-specific information, be fully reviewed, well understood, and pertinent to the situation.

Best practice also dictates that some demonstration be made to show that it was not possible to use a measured mile to evaluate loss of productivity before relying on industry studies.14

Final Thoughts

As evidenced by the studies discussed above, it is widely recognized that adverse weather can impact the productivity of a construction project in many different ways. Industry studies provide interesting insight into how different factors impact productivity and performance on site. They can also act as a tool to help distinguish the loss of productivity due specifically to weather from that due to other factors.

That said, it cannot be stressed enough that the best source of data to calculate the impacts of weather on productivity (or any loss of productivity) is actual project data. Generic industry studies should never replace project-specific analysis methods, including the measured mile, when it is possible to use them. Should an industry study be used to evaluate loss of productivity due to weather, it is of the utmost importance that the selected study not be blindly applied, but rather be fully reviewed and understood, such that it is most appropriate for the work in question and that, where possible, adjustments be made to take into account the actual circumstances on site.

As the industry continues to change and modernize by adopting new technologies, it will be interesting to see what new trends and results any future research into the topic of weather and its impact on productivity will reveal.

- AACE International. “Estimating Lost Labor Productivity in Construction Claims,” AACE International Recommended Practice No. 25R-03: TCM Framework: 6.4 – Forensic Performance Assessment, 2004, p. 8-9.

- American Society of Civil Engineers (ASCE). “Identifying, Quantifying, and Proving Loss of Productivity,” ASCE Standard ANSI/ASCE/CI 71-21, 2021, p. 17-20.

- AACE International. “Estimating Lost Labor Productivity,” 2004, p. 11.

- It is important to note that this is not an exhaustive list, as other studies evaluating the effect of weather on productivity exist, for different sectors, types of tasks, trades and regions.

- National Electrical Contractors Association (NECA). The Effect of Temperature on Productivity: Test Report, 1974.

- Ibid. Recreated by Revay for enhanced visual clarity; refer to the original study as the authoritative source of data to be considered for any potential application.

- Brauer, Roger L., Gerald J. Brown, Edward Koehn, Samuel T. Brooks and Thomas Mahon. AFCS Climactic Zone Labor Adjustment Factors, US Army Corps of Engineers, Construction Engineering Research Laboratory, 1984.

- Ibid. Recreated by Revay for enhanced visual clarity; refer to the original study as the authoritative source of data to be considered for any potential application.

- Lee, Seulkee. Understanding and quantifying the impact of changes on construction labor productivity: Integration of productivity factors and quantification methods, University of California, Berkeley, 2007, p. 357.

- Koehn, Enno and Gerald Brown. “Climatic Effects on Construction,” Journal of Construction Engineering and Management, 111 (2), 1985, p. 129-137.

- Lee, Seulkee. Understanding and quantifying, 2007, p. 363.

- Abele, Gunars. Effect of cold weather on productivity, Society of American Military Engineers DOD Construction R&D Laboratories, U.S. Army Cold Regions Research and Engineering Laboratory, Hanover, New Hampshire 03755, 1986.

- Ibid., p. 62.

- American Society of Civil Engineers (ASCE), “Identifying, Quantifying, and Proving” 2021, p. 19.

The Revay Report is published by Revay and Associates Limited, a Canadian firm specializing in construction claims management and dispute resolution services. We assist our clients by bringing clarity to complex issues. Contents may be reproduced with a credit as to source.

The principles presented in this article are those of the authors and may not necessarily reflect the view of the company. The authors recommend seeking legal advice before applying any principles outlined in this article.

Your comments and suggestions for future articles are most welcome.

Please advise the Montreal office of any change of address or recipient.

Subscribe to

The Revay Report.

You may withdraw your consent at any time by contacting bulletin@revay.com